Die casting is an automated casting

process in which under high pressure and at a high filling speed the liquid

melt is pressed into a mold. Generally alloys with a low melting point are

used. For series and mass production of components this casting process is

particularly suitable because, unlike sand casting, for example, permanent

metal molds are used which after casting do not have to be destroyed. With low

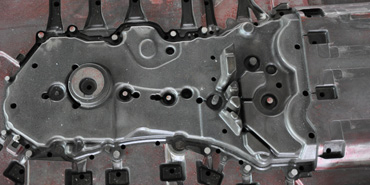

wall thicknesses it is possible to produce large and complex components.

There are two different ways of manufacturing components in die casting: hot chamber and cold chamber die casting. In both manufacturing processes, with a release agent prior to the casting process the mold is sprayed in order to make sure that the subsequently cast part can be easily removed from the mold. However, into the mold cavity the melt is not directly poured, but is first filled into the casting chamber of the die casting machine. From there, by a piston through one or more channels the alloy is pressed into the mold.

Materials

In die casting, to manufacture components non-ferrous metals are used and for a particular application the choice of alloy depends on material properties, budget and weight.

One of the most important materials is Aluminum in Die Casting Process with a share of more than 80 %, followed by zinc and magnesium. However, you can also use copper, lead and tin. The alloys have different properties.

Many advantages are offered by die casting alloys:

- High corrosion resistance

- Good processing properties

- High thermal conductivity

- High electrical conductivity

- High strength and hardness

- Very good EMI/ RFI isolation

Fields of Application

For large series production die casting is mainly used. During the manufacturing process, despite the use of high pressure, a high casting quality is achieved. In the production of very thin (up to 1 mm) (lightweight) components, the die casting process is highly suitable.

Along with this, there are other industries in which die cast parts from Die Casting Manufacturer are used:

- Lighting Technology

- Power Tools

- Aerospace

- Furniture

- Electronics

- Machinery

- Domestic Appliances

| Follow us on Facebook |

No comments:

Post a Comment