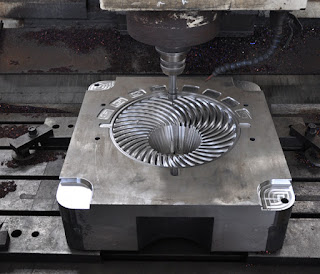

High-pressure die-casting is a technique in which into multi piece reusable molds, liquid metal is pressed over short cycle times.

The mold affects the properties of a die cast part from zamak die casting tooling manufacturer and determines its contours. The weight will not get affected by the action of the filing. Hence, as a result of high-speed fluid flows, the casting processes take place and heat and pressure energy is produced at the end.

For the mass production of, parts made from aluminum, magnesium, and their alloys die casting acts as a forming process .In die casting machines the casting process occurs which are then divided in hot chamber and cold chamber die casting machines.

Accordingly, under special conditions using this die-casting method high-precision and thin-walled castings of high quality and with sharp corners and edges are produced.

Maximum of the nonferrous alloys processed by die-casting consist of zinc, aluminum and magnesium.

While injecting aluminum into a mold, the die-casting done with zamak die casting tooling china is under high thermal and mechanical stresses.

In addition to steel, super alloys are another class of materials that can be used for die-casting molds, which are complex materials that at room temperature and at high temperatures can retain some of their mechanical and physical properties. In aluminum die-casting dies the major issue with super alloys is thermal fatigue, which is a primary reason for failure.

Thermal stresses arise due to change in temperature, which over time in the structure of the mold material may cause damage. This type of damage, which on outer surface appears as tiny cracks, is due to temperature changes. Deep cracks grow gradually and create cracks as gaps. In the lifetime of the die-casting mold the damage caused due to cracks plays a critical role.

Therefore,

in the mold the material that is selected by zamak die casting tooling services for use should have high

temperature stability that too without impulsive failure. From heat checking mold

materials of aluminum die-casting require resistance and high resistance to

soldering and to erosion in a molten aluminum flow of high velocity. Follow on Twitter

No comments:

Post a Comment