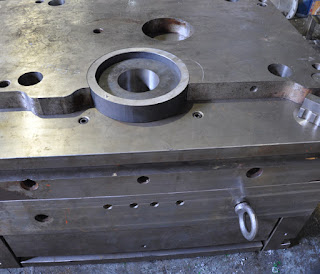

The casting done with Aluminum die casting mold sustains the highest temperatures of operating as compared to all die-cast alloys and it is very lightweight.

Characteristics of Aluminum Alloy:

- Provides good stiffness and strength-to-weight ratio

- Exhibits Good finishing characteristics

- Provides resistance from corrosion

- Quite light in weight

- Operates on high temperatures

- Has good strength and hardness

- It is fully recyclable

- Has excellent thermal conductivity

- Provides High electrical conductivity

Mechanical designers are bombarded with significant benefits because of aluminum’s strength, corrosion resistance, and heat-dissipating properties.

Benefits of Aluminum Die Casting

One important benefit that aluminum die casting offers is that when compared to other die cast alloys it creates lighter parts that too with more surface finishing options. Aluminum operates at the highest temperatures of all the die-cast alloys. So, cast aluminum retains high dimensional stability with thin walls, is versatile, corrosion-resistant, and can be used by any aluminum die casting mold manufacturer.

Applications of Aluminum Die Casting:

Aluminum castings provide their contribution to weight-saving requirements as a result they improved automotive fuel efficiency.

In the telecom and computing industries, aluminum is used in a broad range of networking and infrastructure equipment as there is a requirement of heat dissipation by the RF filter boxes and housings. For housings and electronic connectors, an ideal option is Die-cast aluminum as the best electrical shielding properties and performance is offered by aluminum even in high-temperature.

Recycling of Aluminum Die Castings

Between primary and secondary recycling aluminum die casting, you will see very little functional difference. The use of pure aluminum in casting is quite rare and is due to its cost of extraction. For designers from any industry, aluminum diecasting mold china is their topmost choice because of its ease of use in die casting combined with lighter weight and durability.

Compared to primary aluminum, secondary aluminum is more economical for the production process because it needs only 5 percent as much energy for production. To heat and re-melt the metal die-casting maximum energy consumption is used during fabrication in aluminum.

Find the best aluminum die casting mold manufacturer online to get the best deal. Follow us on Twitter

No comments:

Post a Comment